Drag Chain Conveyors

Two Types of Drag Chain Conveyors for a Wide Range of Material Handling Industries

Drag chain conveyors are the most effective way to move or elevate bulk material and transfer it from point to point. The design, layout configurations, service duty rating, size of the drive, and type of chain and flight assembly are all components that make a significant difference on the quality, durability and longevity of any given drag conveyor.

The term “drag chain conveyor” is widely used throughout the material handling industry, There are two types of this bulk material handling equipment: standard drag chain conveyors and en-masse drag chain conveyors.

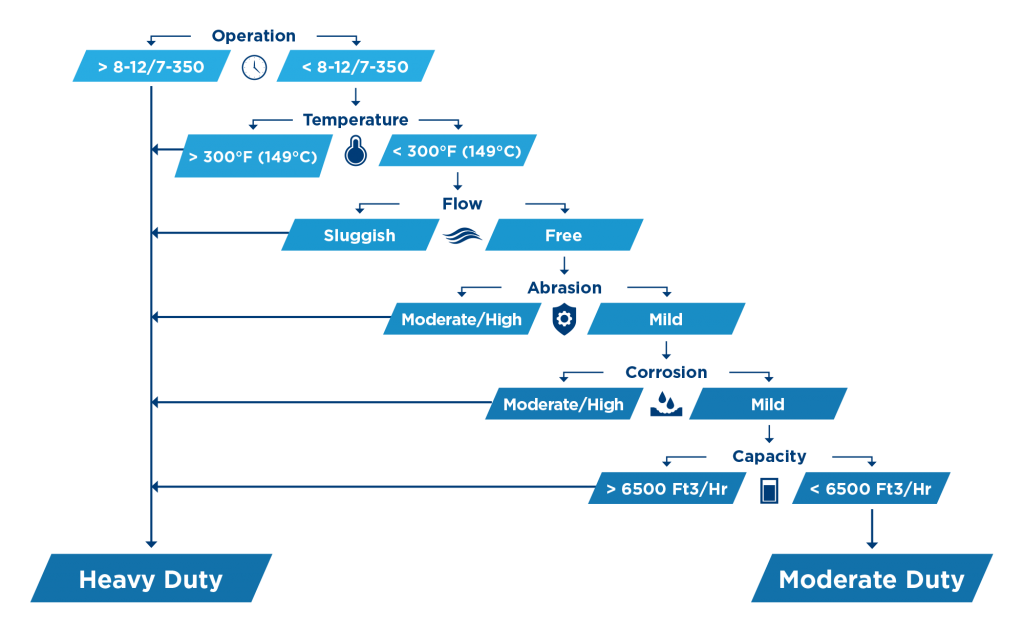

The chart below will help you determine which equipment grade best suits your application: heavy duty or moderate duty. Note: certain materials automatically require a heavy duty conveyor, including potash, glass cullet, bio-fuels, fertilizer(s), petcoke, and fuel feed, fly, or bottom ash.

The Efficient, Versatile Operation of Drag Chain Conveyors

Drag chain conveyors are an optimum choice for bulk processors, power producers, cement manufacturers and minerals processors for minimal material degradation and reduced material loss due to the enclosed housing. The principle operation of both types of drag chain conveyors is based on material movement using a skeletal chain and flight assembly that is drawn along the bottom section of an enclosed housing.

The difference is in the conveying efficiency. Drag chain conveyors use nearly 50% of the available space inside the conveyor housing for material movement, while en-masse drag chain conveyors use up to 90%. By comparison, belt conveyors only use about 20% and screw conveyors only use about 45%. This means drag chain conveyors can move a greater volume of material in a smaller housing, at slower speeds, and with less horsepower. Slower chain speed means less wear, and less horsepower equals lower energy requirements and operating costs.

Drag chain conveyors not only afford the most efficient utilization of space, but they also can move material in a variety of inclines. This layout flexibility comes from the wide range of flight types we offer. Proper flight selection is key to conveying horizontally, on a degreed incline, or vertically.

Our Standard Drag Chain Conveyors:

|

|

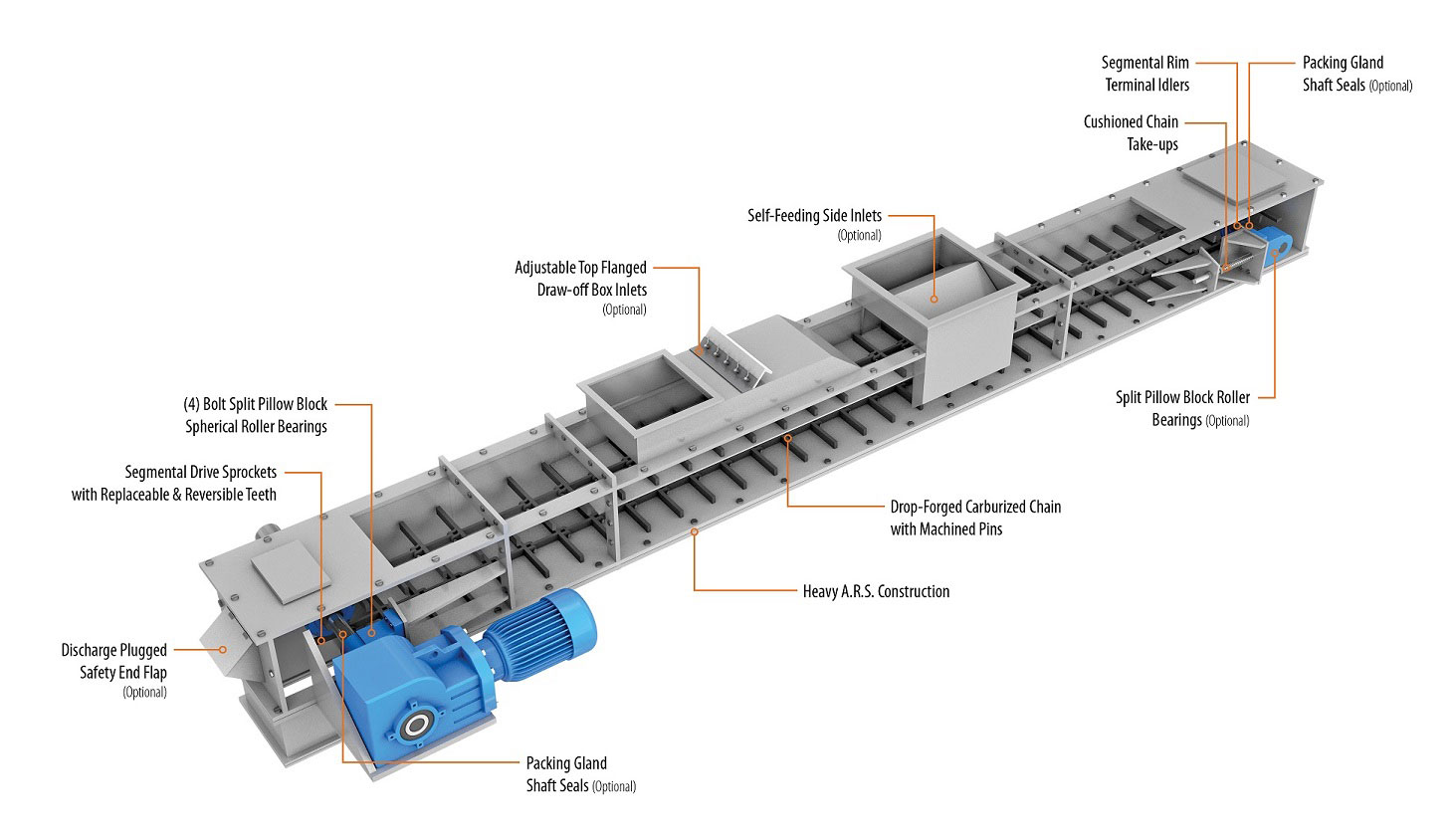

Features and Components

Click the image below to see more detailed information about CDM Drag Chain Conveyors.

Drag Chain Conveying Options

In applications where the use of a dual strand conveyor is warranted due to chain pull and/or capacity requirements, we will often recommend the use of our twin drive station or twin strand conveyors. By providing our twin design we gain the advantages of a dual strand conveyor (added chain pull to allow slower chain speeds and increased sectional area for capacity) along with the advantages of a single strand conveyor (where uneven chain elongation, upset conditions and bent flights have little or no effect on performance).

CDM Slide Gates

We manufacture our own slide gates for each of our en-masse and drag chain conveyors. Our goal is to provide you with the best conveyors and components with the greatest longevity at a competitive price.