Drop-Forged Chain

We’ve Set the Standard in Drag Chain for Over 40 Years

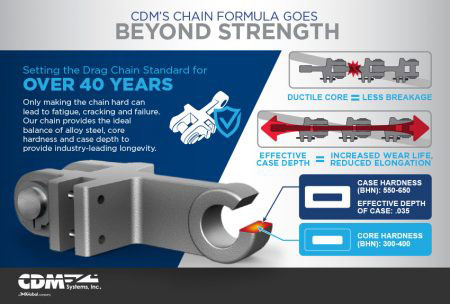

Our chain formula was engineered over 40 years ago with the knowledge that only making the chain hard would induce brittleness and making it malleable would make it susceptible to wear. Neither condition is acceptable for moving bulk materials; too hard and the chain link can fatigue crack causing failure, too soft and the chain is not suited to move hard aggressive materials.

The exclusive combination of a case hardened exterior with malleable core makes the CDM design the strongest, longest wearing chain in the industry.

The exclusive combination of a case hardened exterior with malleable core makes the CDM design the strongest, longest wearing chain in the industry.

The CDM chain is the industry standard and cannot only be found in our conveyors, but inside the conveyors of many well-known conveyor manufacturers. Like you, these manufacturers know that putting the best chain inside the box means that the conveyor will provide the hassle-free results tough industry demands.

Our Chain is Inside Every CDM En-Masse Conveyor

Our chain is unlike any other; rugged, durable, strong, engineered to last. Our exclusive formula balances chemistry, micro structure and heat treating to make it extremely dependable in all types of operating environments. The reliability is in the design, the proof is in the longevity.

Our Exclusive Formula

CDM Systems delivers a complete line of Drop-Forged, case-hardened (60Rc) Conveyor Chains, from 102mm to 260mm pitch, along with multiple connector pin configurations (including custom fabricated) and flight attachments. All chain components combine to provide the most dependable conveying media on the market.

Our CrMn alloy allows us to achieve extremely high tensile strengths and hardness. This translates into increased life, wear resistance, durability and economic value.

-

Our core hardness for strength and ductility is set at 300-400 BHN — this exclusive formula offers high strength and wear resistance while providing a malleable core that prevents breakage.

- Machined yokes provide a tight controlled fit between links.

- Each link is individually pinned for ease of replacement.

- Chain links are totally carburized to provide an effective case hardness of 550-650 BHN(60Rc) — the outer casing is hard for optimum wear resistance.

- Chain link bores are machined to provide a full pin/bore bearing area for maximum strength.

Chain Analysis Reveals Why Formula Matters

The data presented below are the results of an independent lab analysis. The analysis was performed using 10 different industry available drag chains currently selling in the industrial market. Of the 10, we show 6 here because 4 were not even alloy steel making them an unequal comparison to the CDM Systems Chain Formula. The 6 manufacturer’s chain assemblies that use an alloy steel are shown below.

Micro Structure Testing of Various 142MM Pitch Chains

| Micro-Structure | CDM | A | B | C | D | E |

|---|---|---|---|---|---|---|

| Identification Din. Desig.: | 20MnCr5 | 18MnCrB5 | 20NiCrMo5 | 20MnCr5 | 20MnCr5 | 25CrMo4 |

| Core Hardness (BHN): | 300-400 | 300-400 | 300-400 | 415 | 300-400 | 355 |

| Case Hardness (BHN): | 550-650 | 550-650 | 550-600 | 535 | 500-550 | 550-650 |

| Effective Depth of Case: | .035 | .022 | .025 | .010 | .012 | .055 |

The Chain Formulation Means the Difference Between Potential Catastrophic Failure and Operating Long-Term at Full Capacity

The most important feature of any drag chain formula is the effective case hardness depth. Once this case is worn through, elongation will accelerate and become a significant factor in maintenance. However, case depth is not unlimited and not the only factor in building a strong chain. The right formula or case hardness and ductility are critical. Too hard, as with a depth noted above of .055 and the ductility and impact resistance will be compromised and cause failures.

Selecting the Right Chain Configuration

As a general rule, granular material can be handled with a reduced number of flights. Finer, pulverized or micron-sized products typically require additional flight contact or modifications of the flight itself. Contact us for your specific application.

| Application Data Required for Proper Chain Application | |

|---|---|

|

|

With this data, CDM can provide you with a comprehensive proposal on the optimum drag chain for your application.

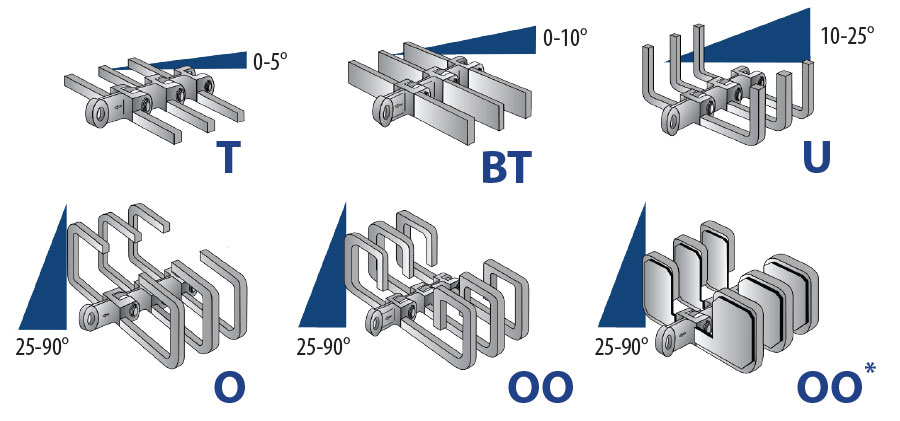

Flight Configurations

The chain conveyor flights illustrated represent the most frequently demanded designs in the industry, but are not the only styles available. The T and BT style flights are used for horizontal trough slight incline applications, normally between 0-12 degrees, while the U flight can be used for horizontal/incline combinations through approximately 25 degrees. The modified BT, O, OO and OO* with filler plates are utilized in horizontal/inclined applications through 90 degrees.

Our Drop-Forged Chain Handles Demanding Operating Conditions

- Fossil Fuel Power Utilities – Coal truck and rail systems, bunker distribution and draw-off, coal and ash recovery conveyors, bottom ash, precipitators, economizers, high-temperature applications

- RDF (Waste to Energy) – Boiler feed systems and ash recovery systems

- Chemical Plants – Raw fertilizers, finished products, truck and rail systems, silo distribution and draw-off

- Cement – Raw meal, rock, limestone, cement clinker from kilns, rejects from mill crushers, finished cement

- Pulp and Paper – Wood chip handling, boiler feeds, ash recovery, bottom ash, precipitators, economizers

- Hazardous Waste – Earth/ash recovery from kilns, medical and chemicals

- Grain Export Terminals – Marine leg unloaders, truck and rail receiving, bin distribution and draw-off conveyors and elevating, ship loading booms

- Cereals, Flours, Feeds – Same as grain terminal with the addition of conveyors for filter cake, desolventizer toasters, extractors, steep tanks, vegetable oils, corn fructose, malt and brewing

- Mining – Receiving, primary and secondary crushers, elevating, smelting, precipitators, dewatering, loadout, etc.

- Steel, Light Ores – Batteries, roasters, leaching systems, all transfer conveyors, etc.