Gates, Valves and Diverters

Create Added Control Over Flow of Bulk Materials

Gates, valves and diverters are invaluable for bulk material handling operations. CDM gates, valves and diverters create versatility to maximize the existing plant space and ensure that conveying systems are running smoothly and efficiently. With an earned reputation for providing customizable gates, valves and diverters made with high-quality materials, CDM’s equipment can handle any bulk material handling need.

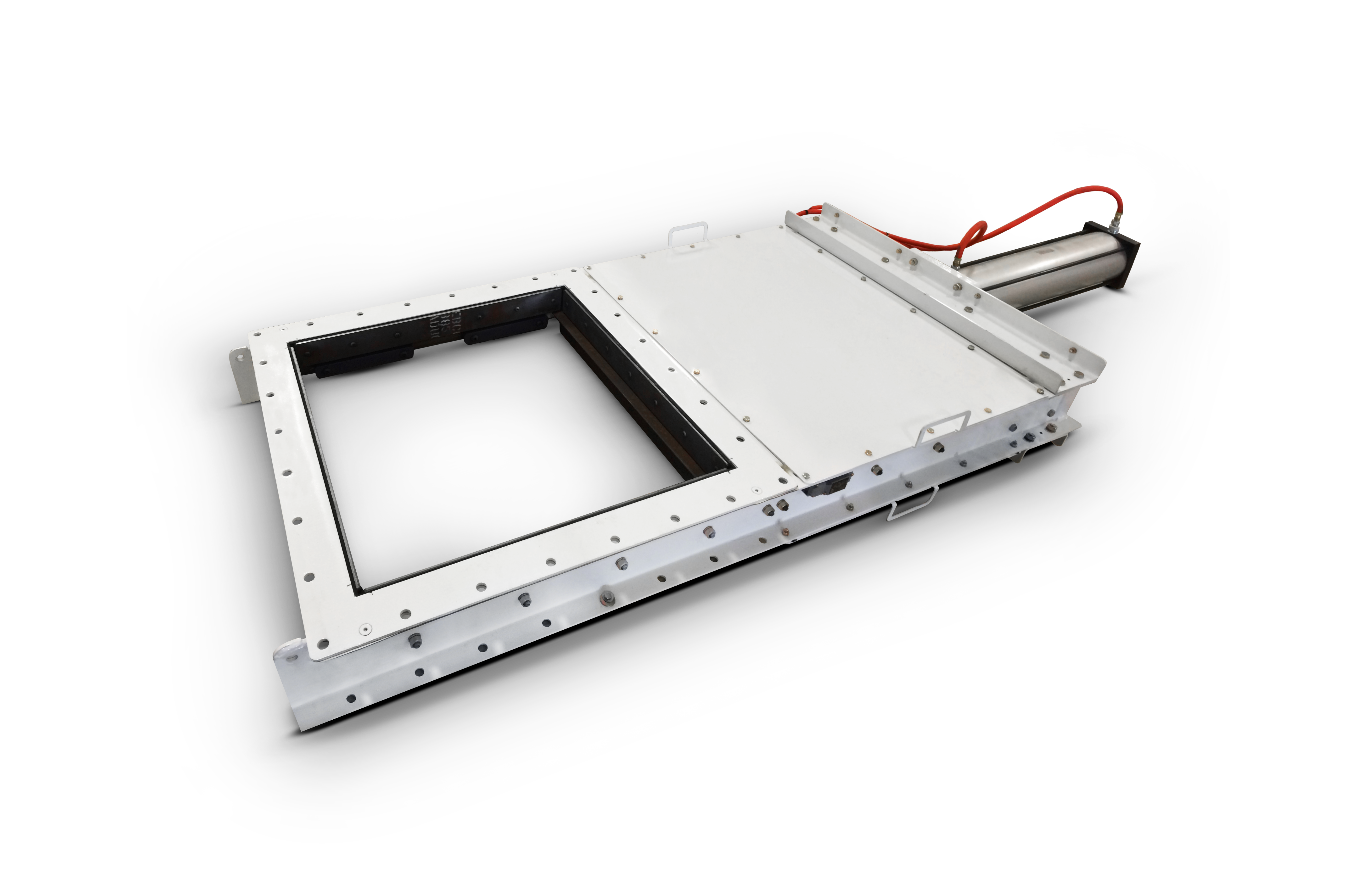

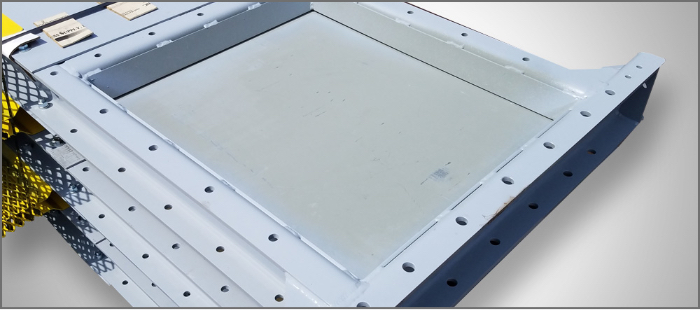

Our gates slide open and closed inside a rigid, completely sealed frame against the flow of material. Inlet or intermediate discharge locations provide metering through the use of linear actuators – or hydraulic or pneumatic transducers – to make it a reliable metering device.

As with any CDM material handling solution, there are several options for our gates to ensure they are customized for your specific plant.

Our clamshell valves are easily adaptable and are commonly used for loadout to trucks or rail cars and under bins or silos. They work best as simple open/closed valves.

Because we will work closely with you, our valves also feature several options related to your specific site:

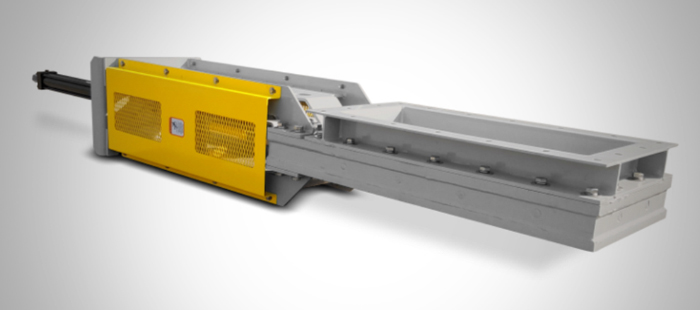

Our diverters control the flow of bulk material from one location to another. They have inlet flange and multiple outlet flanges, using an actuating blade or basket/pan to discharge bulk material to chosen output points. CDM diverters are completely sealed to contain dust and minimize material waste.

Along with our gates, CDM’s customizable diverters make sure they fit the proper needs of your site: