Replacement Chain and Components

Premium Replacement Parts for your Conveying Systems

The core components of drag chain conveying systems are the casing, the drive and terminal, and the chain. The chain is the primary component within the conveyor and must provide the durability and performance required for the application and operating environment. The strength and wear resistance of the link and chain bolt are extremely important to the operating life of the conveyor.

Strength – DIN standards for conveying systems recommend a 5:1 allowable working load vs. ultimate strength of the chain. This safety factor allows for start-up and shock loads.

Wear Resistance – The chain wears from the material itself, sliding friction and pin/bore abrasion when conveying the material and articulation at the sprockets. The ability to resist abrasion during the conveying process is dependent on the optimum intersection of material hardness and ductility.

This is why CDM has created our own unique formula for our drag conveyor chains, which has become the industry standard. We believe a balance of strength, hardness, and ductility along with an engineered chain design profile gives exceptional tensile, shear, and bearing area to the chains inside our conveying systems.

Maintenance Advice and Tips

We take tremendous pride in designing and manufacturing the highest quality conveying systems for your needs. Like all mechanical equipment, the drag conveyors you choose will need routine preventative maintenance (PM). Here are some tips and advice for determining the difference between routine maintenance and the warning signs of possible unplanned downtime without parts replacement. Please review the O&M manuals for detailed maintenance instructions for your specific conveying systems.

Chain Tension

Proper chain tension is among the most important factors to the successful operation of your conveying systems. After an initial break-in period, chain tensioning should be a part of every PM inspection. Tension adjustments can be done in minutes with or without shutting down your conveying systems. When tensioning maintenance begins to increase in frequency, this means you are approaching the limit of the chain case hardness and the chain should be replaced during the next upcoming outage. Measuring the number of links and pins that are removed during normal tensioning can provide insight into the chain’s longevity for future maintenance and planned downtime of your conveying systems.

Sprocket Maintenance

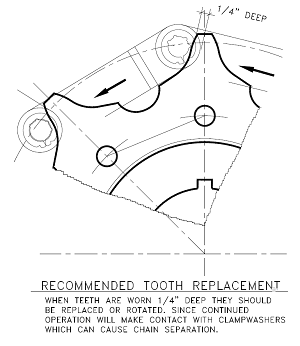

Sprockets are intentionally fabricated and hardened at a slightly lower hardness compared to the chain to minimize wear and potential damage. The illustration represents normal wear of the sprocket due to the continual engagement of the chain on each tooth. The gradual wear of the sprocket down to ¼” below original surface engagement with the chain indicates that the sprocket must be replaced. Operating the chain on worn sprockets creates an improper pitch diameter, which can result in damage to the chain. This condition will shock load the chain and cause “hooking”, resulting in higher stress loads on the chain because of improper sprocket engagement.

Sprockets are intentionally fabricated and hardened at a slightly lower hardness compared to the chain to minimize wear and potential damage. The illustration represents normal wear of the sprocket due to the continual engagement of the chain on each tooth. The gradual wear of the sprocket down to ¼” below original surface engagement with the chain indicates that the sprocket must be replaced. Operating the chain on worn sprockets creates an improper pitch diameter, which can result in damage to the chain. This condition will shock load the chain and cause “hooking”, resulting in higher stress loads on the chain because of improper sprocket engagement.

Critical to proper operation of your conveying systems, sprockets often get overlooked during routine maintenance. Typically, sprocket tooth plates will need to be replaced 1 or 2 times throughout the chain’s lifecycle. New chain should ALWAYS be installed with new sprocket tooth plates.

Sprocket Cleaners / Return Rails

Sprocket cleaner return rails are the first defense to worn sprockets, improper chain tension and material build-up within the sprocket itself. CDM fabricates these rails in short sections which can easily be replaced during a short outage or normal PM schedule. Over time these rails will take the brunt of the wear for the return rail assembly. If wear is observed of 1/4″ or greater from the original installation thickness, the sprocket cleaner rail should be replaced.

Lubrication

Lubrication requirements for conveying systems are straightforward. Drive and terminal station bearings require normal lubrication with grease. The recommended intervals will vary depending upon the specific service duty of each conveyor. There are no intermediate bearing locations in our conveying systems. The only other lubrication areas are the gear reducer and the reducer bearings. Each require normal level checks and oil changes as specified by the manufacturer. In some cases, greasing the reducer bearings is also necessary. The motor is the only other item that will require normal grease per the OEM’s recommendations.