Refinery

Drag Chain Conveying System Supports Refinery Filter Cake Recycle and Reuse

Download PDF

CHALLENGE

A large oil company sought to expand refinery operations at one of their global locations. The expansion required an effective way to handle the filter cake at a new refinery. The high-volume of filter cake coupled with the system redundancy required by the producer meant numerous conveyors would be needed to meet specifications. In addition, the corrosive environment required conveyor design to provide reliable, long-term, 24/7 operation.

PRODUCTS UTILIZED

Drop-Forged Chain

En-Masse Conveyor

Engineered Material Handling System

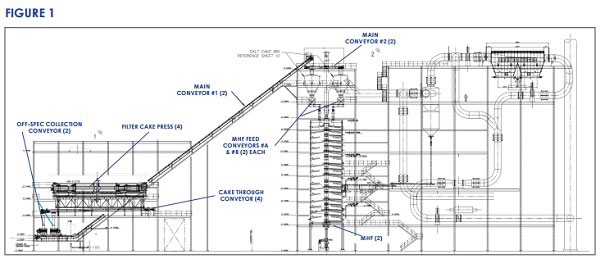

The filter cake handling process involved automatically taking the cake from the discharge of each of four filter cake presses and transferring the material to two multiple hearth furnaces. Figure 1 is a 2D schematic of the filter cake processing layout for a single system; the entire system had 4 identical units totaling 64 individual conveyors.

The requirements of the material handling system involve effectively moving filter cake from the filter presses to a series of multiple hearth furnaces (MHF) where the material is used to fuel the burning process.

After the filter cake is elevated 150 feet at a 40° incline the filter cake material is transferred into the main horizontal conveyors (#2). The main conveyors deliver the filter cake material to either of two filter cake surge bins. Dual strand metering drag conveyors located at the bottom of the surge bins controlled by VFD’s then deliver a determined rate of filter cake material.

The rate is determined for optimum burn efficiencies to either of two transfer conveyors via a diverter chute which then feed the two multiple hearth furnaces. The furnaces burn the filter cake as a reclaimed energy source. The furnace requires the pressed material to meet specific standards for dryness and material consistency. If the filter cake contains too much moisture or is too dense, the burn process will be less efficient.

To achieve optimum processing within the MHF, an inspection process at the discharge of the filter cake press allows for off-spec material to be discharged separately. The offspec material required a separate hopper and conveying system to effectively and automatically transfer the unusable material to a storage container.

To achieve the material transfer rates of the system and to provide reliable operation in a corrosive environment the oil producer, working with a general contractor looked to the CDM drag chain conveyor as the optimum selection for the project.

A High-Volume Application Requires the Right Conveyor

The cake trough, collecting, and the main dual-strand conveyor have a required capacity of 53,000 lb/hr (24,000 kg/hr). The cake bin conveyors each holds a material movement rate of 11,023 lb/hr (5,000 kg/hr). The drag conveyors were selected with dual strand and cross flights to achieve the required capacity with a material bulk density of 575Kg/M3.

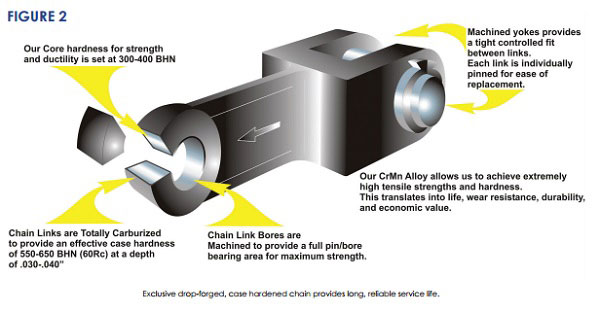

The exclusive CDM CrMn forged steel alloy chains have a core hardness of 300-400 BHN and are machined and carburized for a case of 550-650 (Figure 2). This configuration, coupled with the thickness, height, width, and spacing of the flights minimized chain pull and mitigated unplanned downtime risk. To support longevity in a 24/7 refinery operation the housing was constructed of a Ferritic Stainless Steel.

Conveyor Reliability Increases Productivity

A refinery, like many large scale chemical and mineral processing facilities, relies on the 24/7 operation of the conveyors to carry bulk material. This is true of raw materials for process or process by-products for recycling and/ or reuse.

When a conveyor goes down unexpectedly because of design failure the productivity of the facility is compromised, and workers and the company are exposed to unnecessary risk. Large-scale production facilities have many confined space environments, hazardous material components and dangerous utilities and operations that when exposed to emergency downtime and repairs have the possibility for injury or extended outage.

Engineering and selecting the best conveying technology in the design phase for a given application is critical to the longevity of equipment and productivity stability.

Browse By Benefit

Categories

- Blog (40)

- Case Studies (9)

- News (7)

- Product Information (7)

- Tech Briefs (3)

- Technical Documents (33)

- Uncategorized (1)

- Videos (12)

- White Papers (5)