Drop-Forge ChainIndustry Leader For 40+ Years.

Our chain is unlike any other: rugged, durable, strong, engineered to last. Our exclusive formula balances chemistry, micro structure and heat treating to make it extremely dependable in all types of operating environments. The reliability is in the design and the proof is in the longevity. There’s a reason why our drop-forge chain is in both our conveyors and the conveyors of many well-known manufacturers.

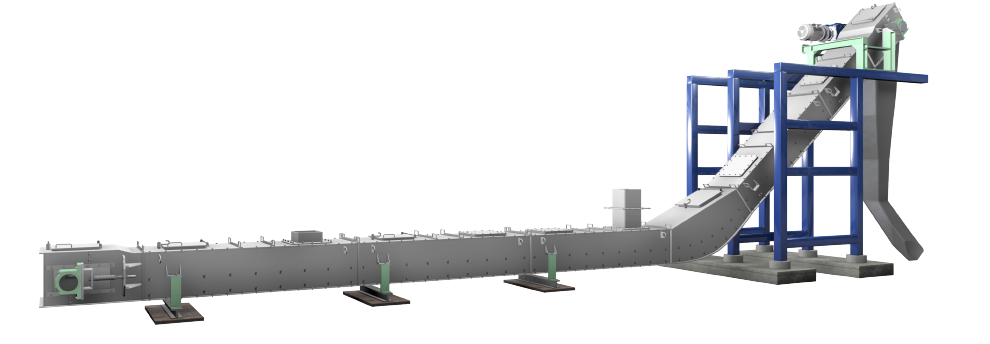

Drag Chain / En-Masse ConveyorVersatile. Practical. Efficient.

Drag chain conveyors are the most effective way to move or elevate bulk material and transfer it from point to point. The design, layout configurations, service duty rating, size of the drive, and the type of chain and flight assembly are all components that make a significant difference on a drag conveyor’s quality, durability and longevity. CDM’s drag chain conveyors are a solid choice for bulk processors, power producers, cement manufacturers and minerals processors looking for minimal material degradation and reduced material loss due to the enclosed housing.

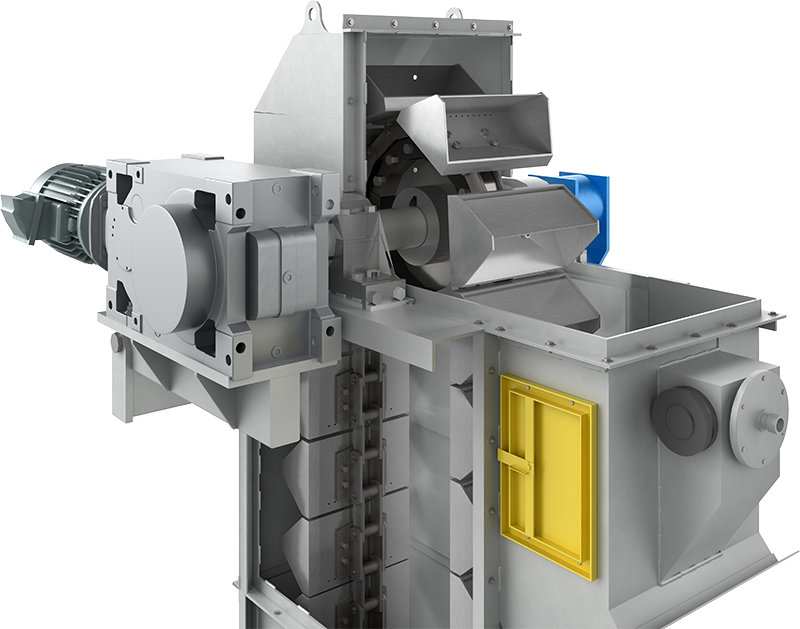

Bucket ElevatorSolve Your Vertical Conveying Problems.

Before we spec out any project, we work directly with you to understand your plant flow and business needs. Our customized bucket elevators are available with your choice of options (centrifugal or continuous discharge; type of steel/material; belt or chain) to best suit your specific application. The type of commodity you’re working with and the speed at which you need to move that material are among several aspects that will influence your bucket elevator selection.

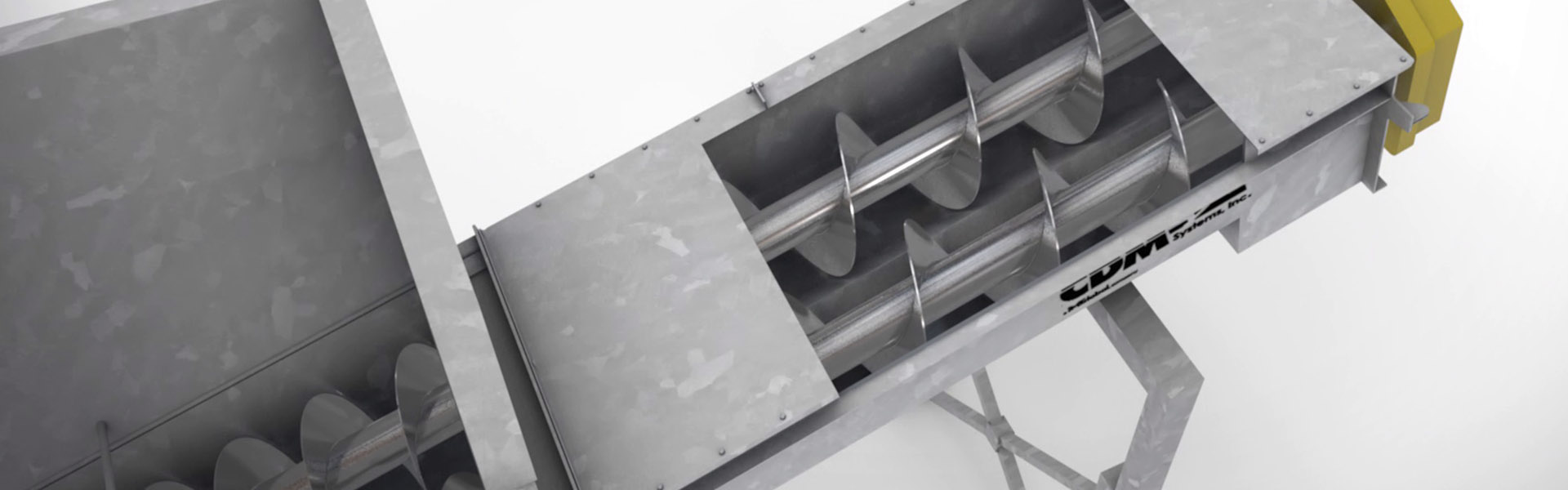

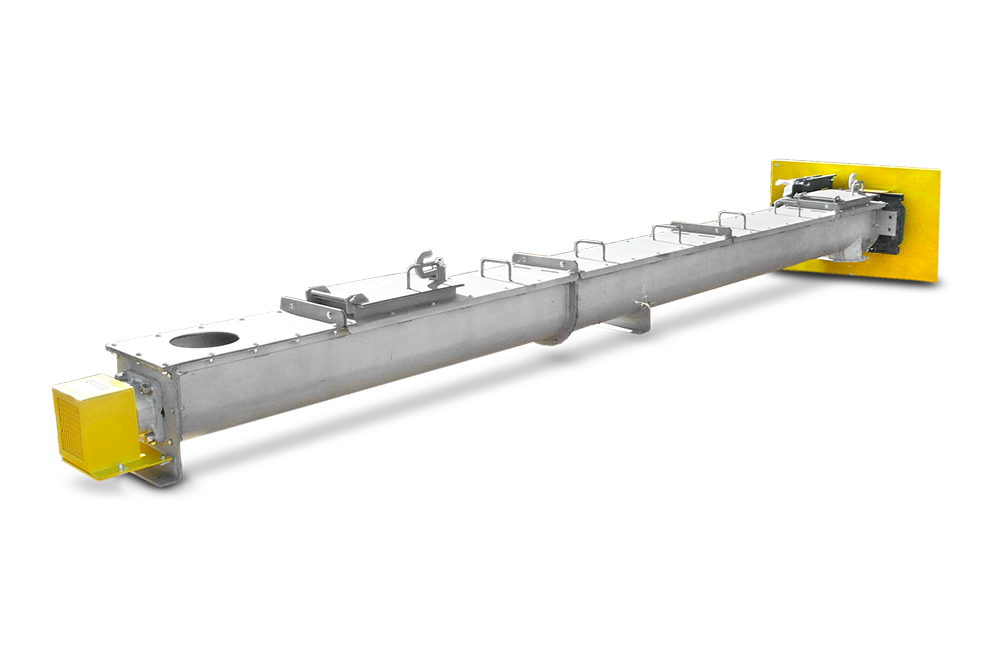

Screw ConveyorCustom-Made Screw Conveyors Keep Your Facility Moving.

Screw conveyors handle the full gamut of materials – from semi-fluid to dry and from sluggish to free-flowing. However, a screw conveyor is not a one-size-fits-all solution. If misapplied, this equipment will experience breakdowns that result in lost revenues from production downtime. As with any CDM material handling solution, we will design your screw conveyor to your exact specifications, as dictated by your specific application needs.

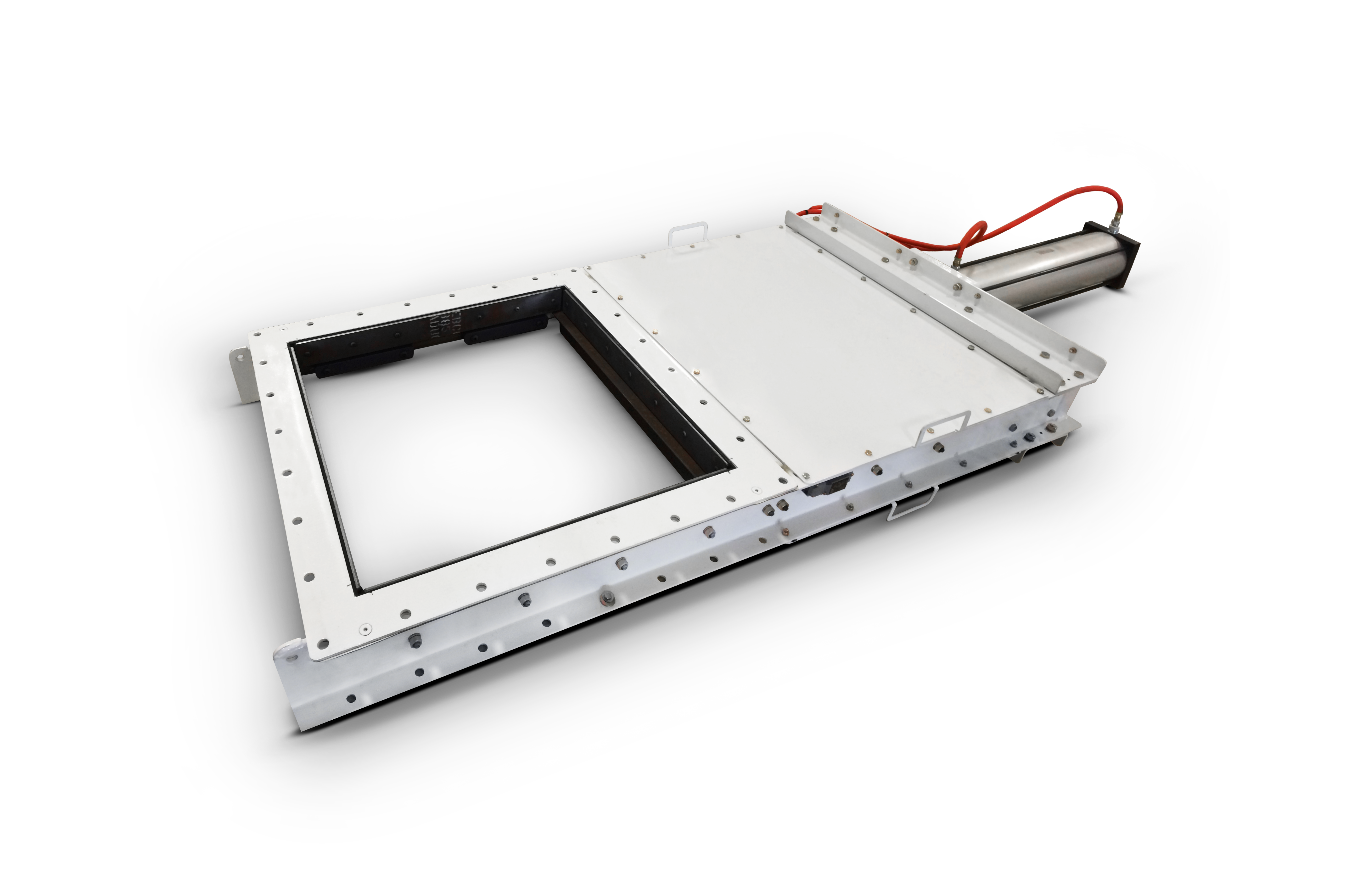

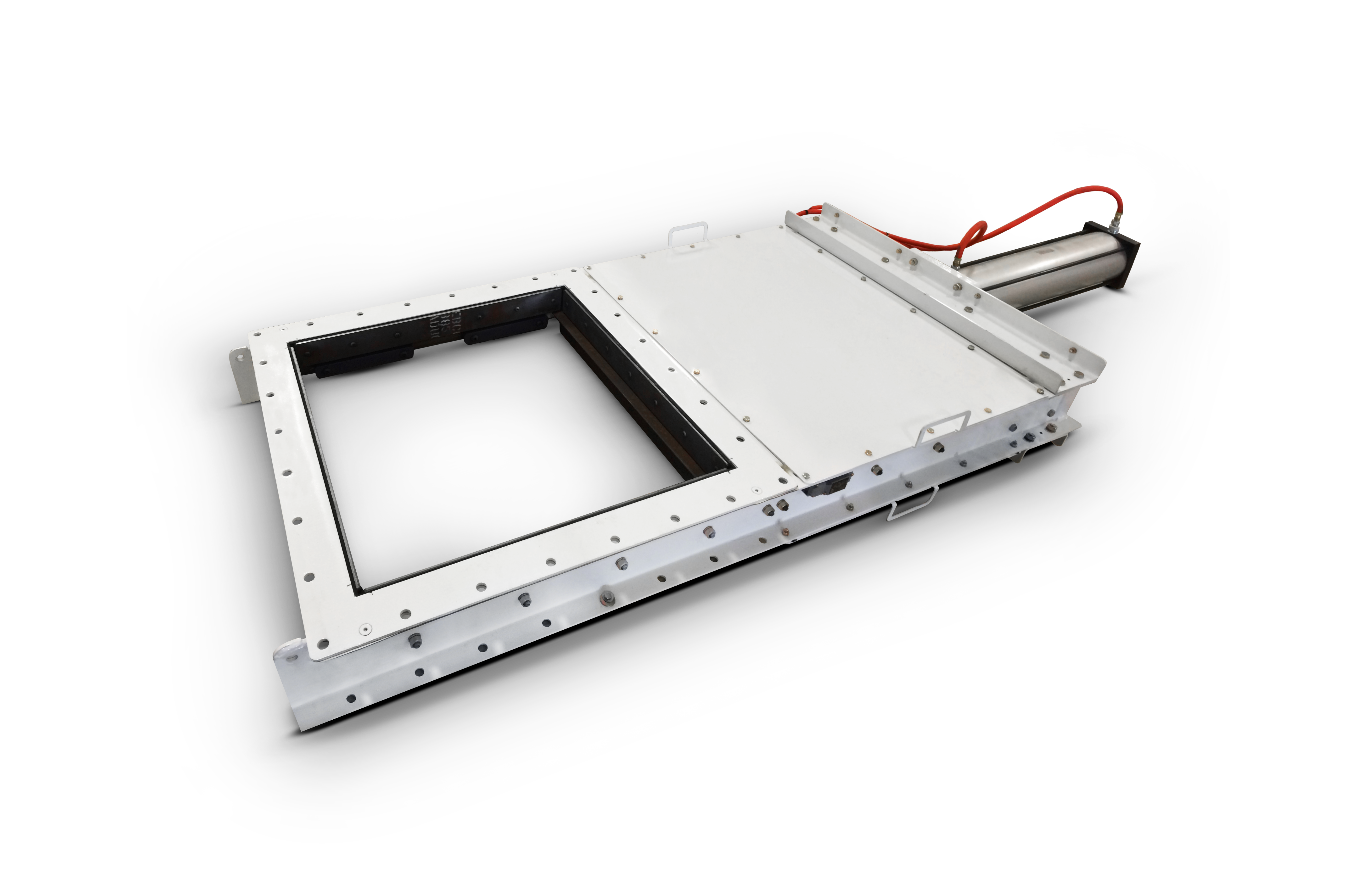

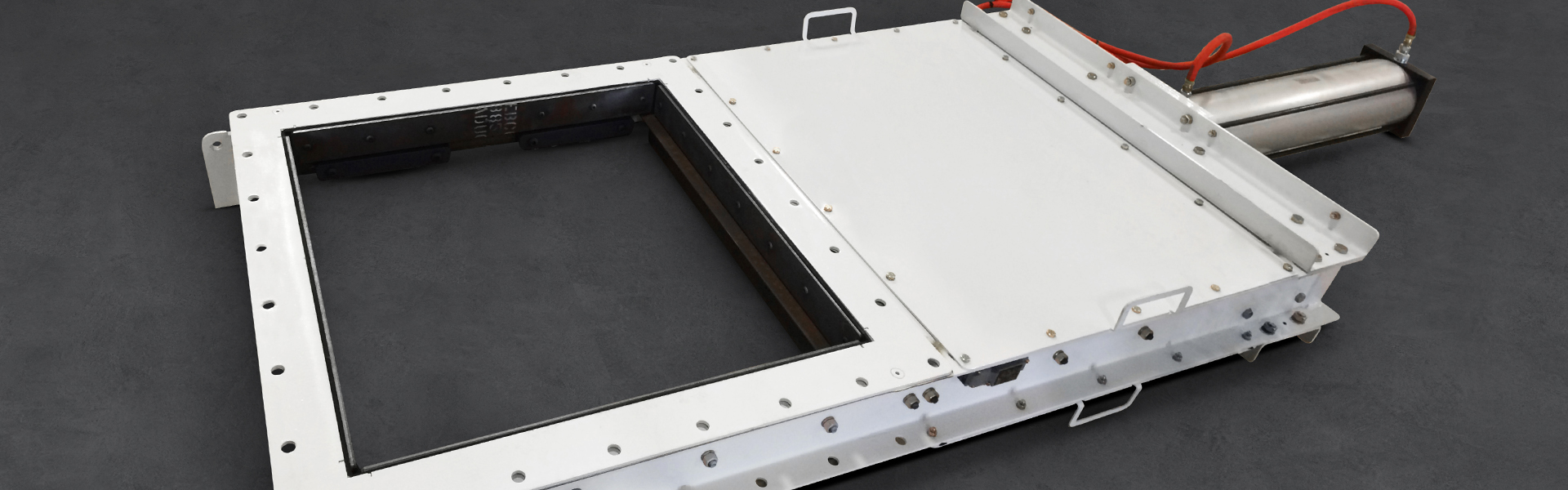

Gates, Valves and DivertersControl Flow of Materials In Your Process.

Gates, valves and diverters are invaluable for bulk material handling operations. CDM gates, valves and diverters create versatility to maximize the existing plant space and ensure that your processes are running smoothly and efficiently. With an earned reputation for providing customizable gates, valves and diverters made with high-quality materials, CDM’s equipment can handle any bulk material handling need.