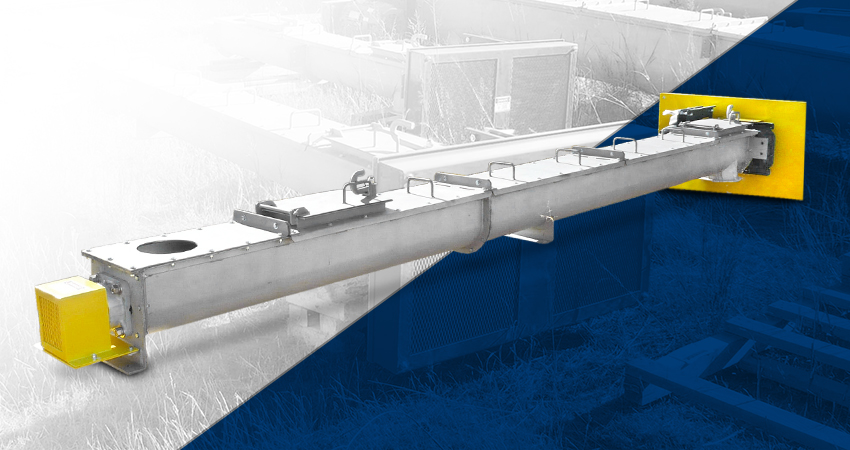

Solving the Industry’s Biggest, Most Complex Conveying Problems

CDM delivers custom-engineered systems to address every challenge in the Mining Industry CDM was started more than 40 years ago with a mission to provide our clients with the longest lasting, most efficient conveyor systems for their specific applications. We have developed a balance in housing design, chain selection, speed and flight style to provide maximum productivity and durability. Today […]