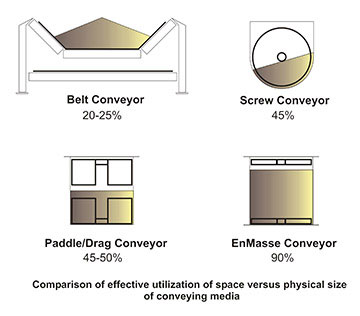

Conveying Comparison: What Are the Most Efficient Conveying Technologies for Bulk Material Handling?

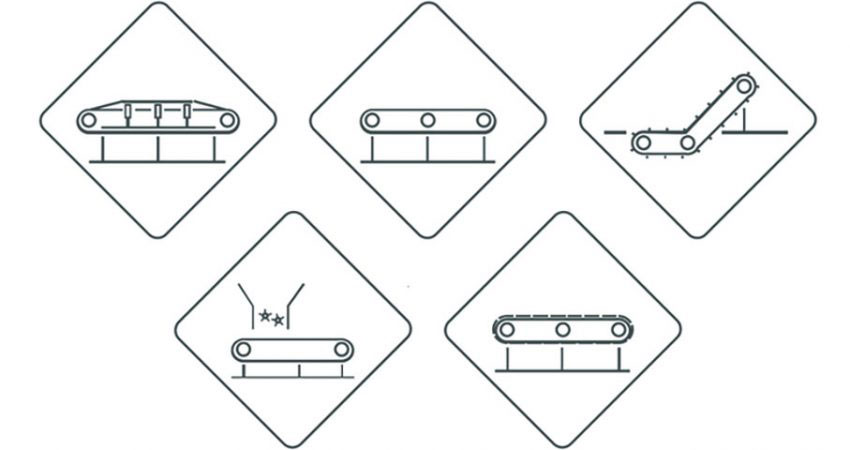

There are many different conveying technologies available. To be educated on the distinct types and the best markets for which they are efficiently utilized is the first step. Below are the different types of conveyors used for bulk material handling and the advantages and disadvantages. Want to skip ahead? Click here to download the full technical brief by an industry-leading […]