CDM Systems Drag Conveyors – Features and Benefits Video

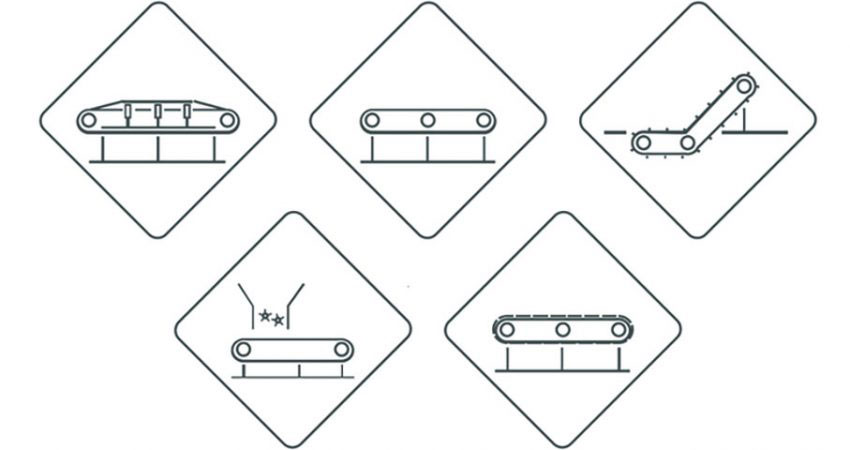

While each conveyor is designed and built on a per suit / application basis we include these following features within nearly all of our conveyors. Our objective to supply a piece of equipment to our customers that not only exceeds their expectations in performance but allows for ease of maintenance, replacement of normal wear items, and a design that mitigates […]