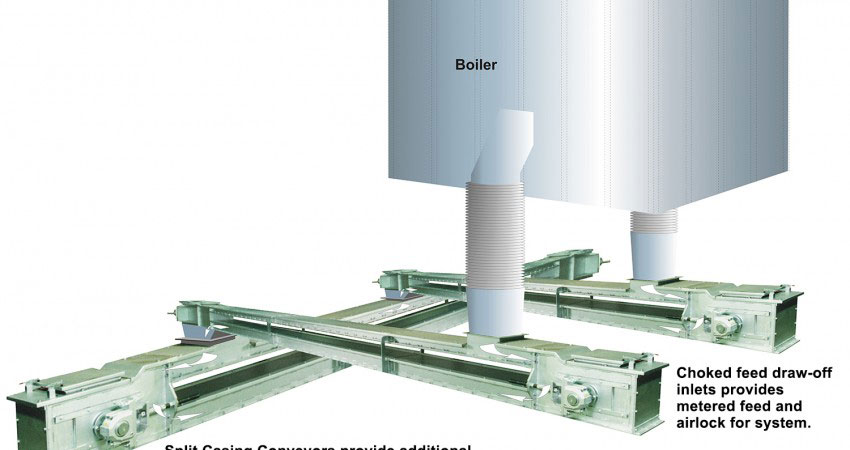

Top En-Masse Design Elements for Ash Handling

Designing the conveyor from the inside out is a great method when engineering a piece of equipment. The full application and site details are collected, then the design work can begin with selecting the optimum chain for the application. Once the chain is chosen, the frame and components are then designed around it. That was the case for a new […]