Preventative Maintenance Guide

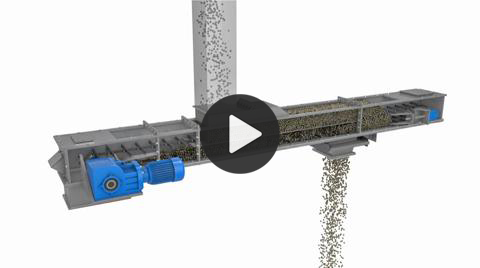

We often get asked how long our equipment will last. The answer: it depends. Preventative maintenance will help you get more out of your equipment. That’s why we put together a handy Preventative Maintenance guide that will help you with: Proper chain tension Sprocket wear and tear/bearings Return rail and housing wear and tear Chain replacement Click here to download […]