Case Study: Pulp and Paper Manufacturer

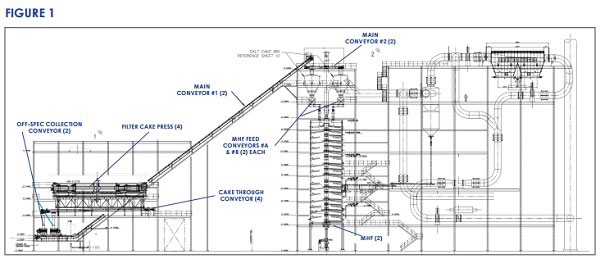

Pulp and Paper Mill Cuts Maintenance Costs and Improves Operations with Salt Cake Conveyor Redesign CHALLENGE A Pulp & Paper facility in Northwestern Pennsylvania had extensive issues with conveyor corrosion and subsequent failure on the salt cake handling system due to the corrosive vapor that was generated when the cake was introduced to a black liquor tank. The […]