Don’t Get a Pickup When You Need a Sports Car (Or Vice Versa)

There are many similarities between a pickup truck and a high-performance sports car.

Both have engines, both have four wheels, and both can go 100 miles per hour.

The biggest difference between them is this: one can reach and maintain that speed easily, while the other will eventually break down because it’s not designed and built for the task.

Similar differences between conveying equipment must be considered when the time comes to specify, purchase and install a material handling system. The available options may appear to have the same components and an identical ability to move material from point A to point B, but rarely is that the case.

This is what’s known as “marginal sizing.” In theory, all of the solutions should work, as illustrated by the pickup truck/sports car comparison. In practice, however, one solution will be ideal while the others will be undersized, underbuilt and eventually cause headaches due to equipment failure and expensive downtime.

Looking at the Big Picture

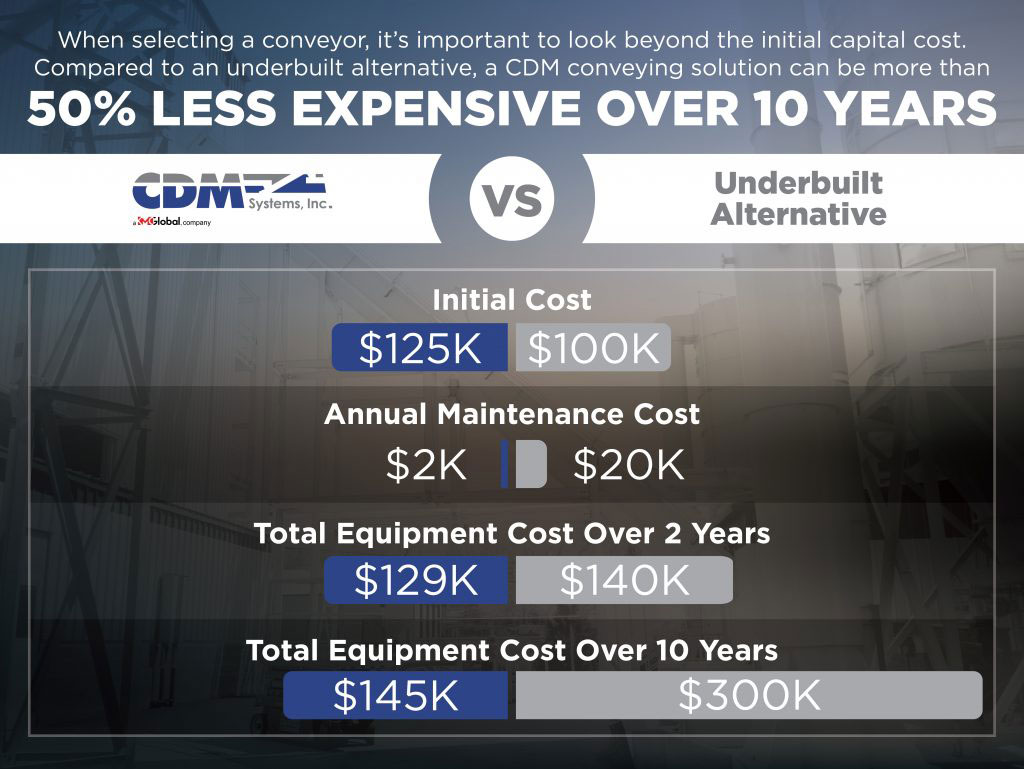

That’s why it’s so important to look beyond the initial capital cost and assess the suitability of a conveying solution as it applies to your specific application. Of course, not allowing the initial cost to influence an equipment decision is easier said than done – especially if the cost difference between available options is significant. However, if a conveyor that costs $100,000 requires an annual maintenance expenditure of $20,000, it’s certainly worth considering a $125,000 piece of equipment that only costs $2,000 a year to maintain.

It’s easy to crunch the numbers and see how reduced maintenance costs can quickly offset a larger initial cost. It can be more difficult to understand or anticipate the following additional factors that contribute to the overall cost of an equipment solution.

1. The Speed of the System

Here’s where the pickup truck/sports car analogy applies in reverse, because it’s not always desirable or economical to move material at higher speeds. For example, a 19-inch conveyor will cost more up front than a 15-inch conveyor, but the larger flight capacity means you can run the equipment at a slower speed. This not only allows you to use less energy to achieve the same throughput, but you can also increase the life of the conveyor exponentially. That’s because component wear isn’t linear or directly proportional to speed. If you double the speed of a conveyor, you more than double the wear to the chain and drive sprockets, which requires more frequent maintenance and can increase the likelihood of equipment failure.

2. The Characteristics of the Material

Marginally sized equipment can’t handle fluctuations in bulk density and flow characteristics that can occur in the same material and in the same facility. Grain or any other type of material that is hygroscopic can have a different moisture content from one day to the next depending on how it was transported or stored. A conveyor or bucket elevator that handles dry material well but has difficulty with wet material could suddenly break down due to the presence of unexpected moisture. Additionally, raw materials like coal can come in the form of 1-2″ chunks or fines from the bottom of a rail car that were created by compression during transit. Each material size must be handled differently, and not all conveyors are capable of doing so. Accounting for the variability in each commodity in the up-front design of a conveying system can mean the difference between a successful and unsuccessful equipment solution.

3. The High Price of Equipment Replacement

The cost of installing a conveyor system comprises a significant portion of the overall equipment expenditure. If you invested in a system that was less expensive than other options, but it ended up being undersized or otherwise insufficient for your application, you will need to incur the cost of another system as well a second installation. Spending more at the outset on the correct piece of capital equipment could end up saving you 2-3 times the cost of the equipment down the line simply by eliminating the need for multiple installations.

At CDM, we’ll ask the right questions at the beginning of the specification process to help you avoid marginally sized equipment and arrive at the optimum conveying solution that accounts for all of the variables in your unique application. In other words, if you need a pickup truck, we won’t give you a sports car, and vice versa.

———

About CDM

The CDM story is about recognizing every industrial operation is different, as are their conveying challenges. A custom-engineered conveying system is a cost-effective approach to any operation willing to look at the value of having a partner who is vested in your success and one who stands by their product. CDM has earned more than 91 percent repeat business because we’re more than just a conveying systems manufacturer – we’re a business partner.

For further information contact:

Andrew Parker, President CDM Systems, Inc.

Browse By Benefit

Categories

- Blog (40)

- Case Studies (9)

- News (7)

- Product Information (7)

- Tech Briefs (3)

- Technical Documents (33)

- Uncategorized (1)

- Videos (12)

- White Papers (5)