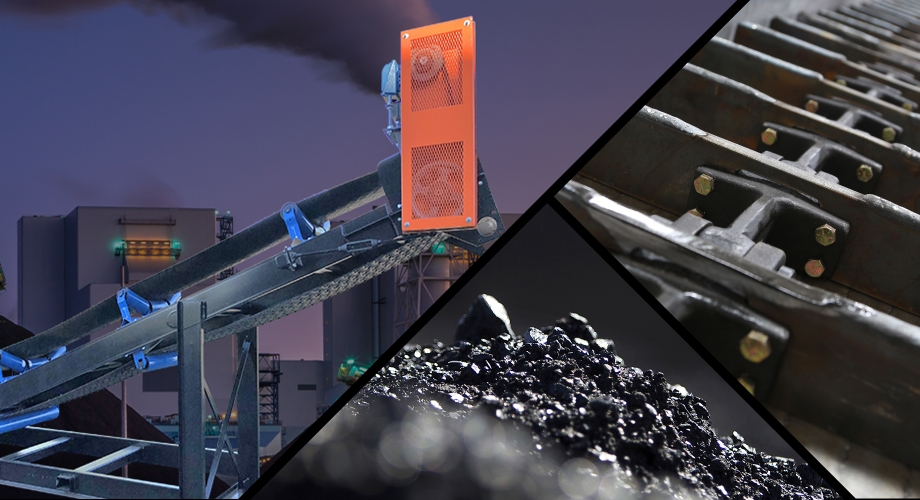

From Waste to Resource: The Importance of Custom Conveyors for Waste Coal Handling in Power Generation

The Appalachian coal regions contain massive stockpiles of coal refuse, spread across thousands of acres of land in Pennsylvania, Maryland, Virginia, West Virginia, Ohio and Kentucky. There are hundreds of millions of tons of waste coal, leftover when old coal mines closed, that is used for fuel at power generation facilities. With many of these coal-burning power plants still active, […]