Severe Duty Drag Conveyors

From Ash to Zinc, Our Heavy Duty Conveyors Handle It All in the Most Demanding Material Handling Applications

With their rugged design, CDM’s heavy duty drag chain conveying systems deliver superior performance when handling abrasive, corrosive materials in severe, hostile environments with inlet temperatures up to 1000°F. These drag chain conveyors can handle extremely high capacities and are capable of moving tons of material per hour over relatively great distances.

With their rugged design, CDM’s heavy duty drag chain conveying systems deliver superior performance when handling abrasive, corrosive materials in severe, hostile environments with inlet temperatures up to 1000°F. These drag chain conveyors can handle extremely high capacities and are capable of moving tons of material per hour over relatively great distances.

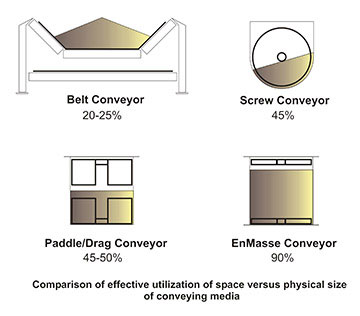

Our heavy or severe duty drag chain conveyors are also the most efficient type of bulk material handling equipment for high-volume conveying. In horizontal applications, these conveyors utilize up to 90% of the cross-sectional area. Compared to other conveying technology, a heavy duty drag chain conveyor requires a smaller footprint to move the same or greater capacities of bulk materials.

More Than Just Muscle: The Operating Principles of En-Masse Conveying

Although the names are similar, an en-masse drag chain conveyor is very different in principle from a standard drag conveyor. En-masse drag chain conveyors move bulk material using a skeletal chain flight through a rectangular section of the material. The motion imparted on the bottom surface of the trough by the chain and the shear friction between the particles conveyed moves the material from point A to point B. They can move bulk materials in various configurations: horizontal, inclined, vertical, L-path, Z-path and loop. This makes our en-masse conveyors ideal for retrofits, new applications and bulk material handling in confined areas.

This unique method of conveying bulk materials smoothly, gently and economically in a dust-tight, AR-steel casing, across planes and around bends, is what makes the En-Masse Chain Conveyor the optimum selection for high-volume bulk material handling with no degradation. There is no internal disturbance or pressure on the material and the load can be discharged at any opening.

Our Heavy or Severe Duty Drag Chain Conveyors:

|

|

The Chain Moves Material

When considering drag chain conveyors for a heavy or severe duty material handling application, the chain is the most critical component to evaluate. The hardness formula, design, flight selection, strength, and wear resistance are critical factors we use to manufacture a drag chain that will offer the durability and reliability required to meet the demands of today’s material handling plants. If the chain fails, production levels and delivery deadlines are missed. For 40 years, our chain has set the industry standard for quality. We have developed and perfected the optimum chain formula for strength and longevity. That’s why we are the conveying industry’s single greatest chain supplier to end users and OEM conveyor manufacturers. When you have a CDM chain, you know you have the best.

Watch the live chain movement through the drag chain conveyor below: