How the Turtle Philosophy Applies to CDM’s Superior Conveyor Chains

Comedian and social activist Dick Gregory once remarked that he lived his life by the Turtle Philosophy: “Hard on the outside, soft on the inside, and willing to stick my neck out.”

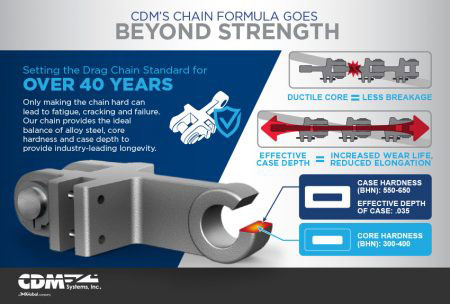

In a nutshell – or a turtle shell, if you will – this is the basic philosophy behind CDM’s exclusive conveyor chain formula: Hard on the outside to deliver industry-standard durability in aggressive, heavy-duty applications; softer on the inside to prevent breakage in those same applications; and a case depth that achieves an optimum balance of the two.

Let’s look at each of those attributes individually:

Let’s look at each of those attributes individually:

Case Hardness

The chain is the primary component within any Drag Chain or En-Masse conveying system (the other components are the casing and the drive and terminal). As such, the chain must provide the durability and performance required for the specific application and operating environment. Our chain links are totally carburized to provide an effective case hardness of 550-650 BHN, and our CrMn alloy allows us to achieve extremely high tensile strengths and hardness. This translates into increased life, wear resistance, durability, economic value and the ability to withstand operating temperatures in excess of 1,000°F.

Core Hardness

Simply having the hardest chain isn’t the key to strength and long conveyor life. When our founders engineered our exclusive chain formula over 40 years ago, they knew that only making the chain hard would induce brittleness, which leads to cracking and failure. So they developed a chain with a softer core beneath a case-hardened exterior. Our core hardness for strength and ductility is set at 300-400 BHN, which offers high strength and wear resistance while providing a malleable core that prevents breakage.

Case Depth

The most important element of any drag chain formula is the effective case hardness depth. The right balance between case hardness and ductility are critical. If the case is too deep or thick, the chain as a whole becomes too hard, which compromises the ductility and impact resistance and causes failures. If the case isn’t deep or thick enough, it will wear through more quickly, causing elongation to occur prematurely and become a significant maintenance issue.

Micro Structure Testing: CDM vs. the Competition

The infographic illustrates the results of an independent lab analysis of our chain and the chains of five competitors that also are constructed of an alloy steel. Most of our competitors’ chains have the same or similar case and core hardness. The key difference is in the case depth. We’ve identified a .035 depth as the sweet spot, while our competitors fall significantly above or below that number, which means their chains are either harder or softer overall than ours. At CDM, neither condition is acceptable for moving bulk materials; too hard and the chain link can crack from fatigue and fail, too soft and the chain is not suited to move hard, aggressive materials.

We believe our combination of strength, hardness, and ductility means the difference between potential catastrophic failure and operating long-term at full capacity. Our chain is unlike any other; rugged, durable, strong and engineered to last. Our exclusive formula balances chemistry, micro-structure and heat-treating to make our chains extremely dependable in all types of operating environments. That’s how CDM sticks its neck out for our customers – by partnering with them to take on the biggest conveying challenges in a variety of demanding industries.

The reliability is in the design, the proof is in the longevity – and our version of the turtle philosophy is how CDM builds the strongest, longest wearing chain in the industry.

———

About CDM

The CDM story is about recognizing every industrial operation is different, as are their conveying challenges. A custom-engineered conveying system is a cost-effective approach to any operation willing to look at the value of having a partner who is vested in your success and one who stands by their product. CDM has earned more than 91 percent repeat business because we’re more than just a conveying systems manufacturer – we’re a business partner.

For further information contact:

Andrew Parker, President CDM Systems, Inc.

Browse By Benefit

Categories

- Blog (40)

- Case Studies (9)

- News (7)

- Product Information (7)

- Tech Briefs (3)

- Technical Documents (33)

- Uncategorized (1)

- Videos (12)

- White Papers (5)