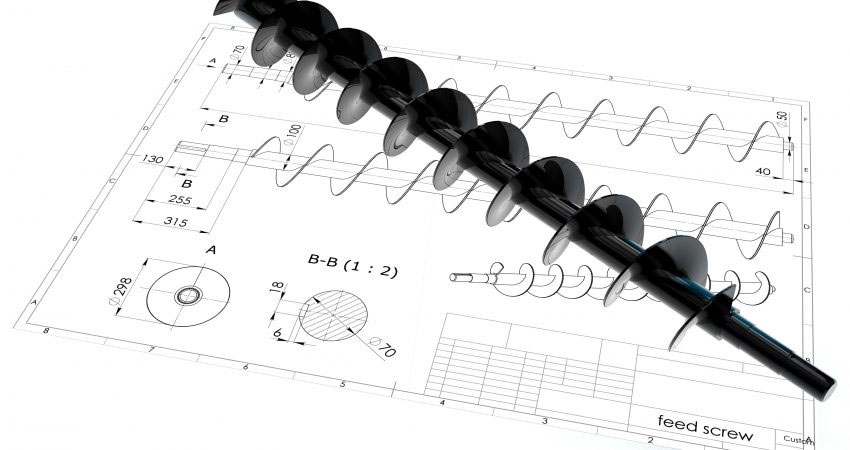

The Number One Factor That Can Cause Screw Conveyor Downtime

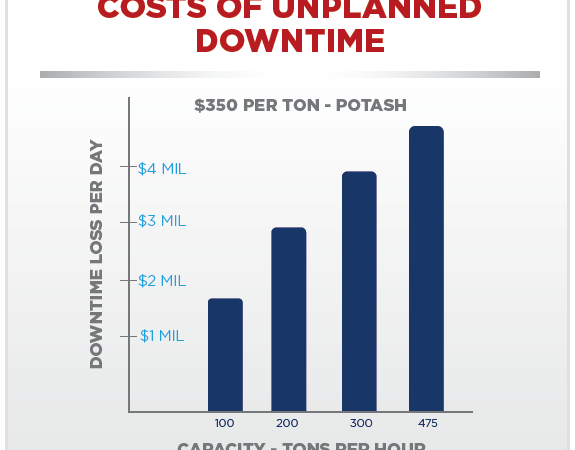

In any manufacturing or production operation, one of the biggest variables in calculating reliable profit projections is the constant reality of downtime and the related financial costs. While the exact number depends on the specific business and industry, an International Society of Automation study estimates that downtime costs the manufacturing industry nearly $650 billion each year. Ignoring the financial cost of […]