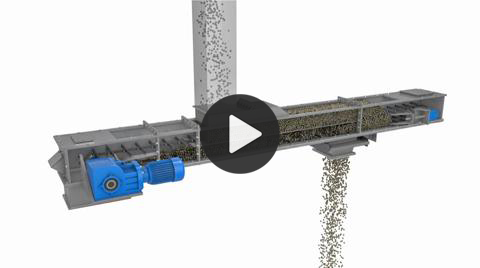

Experience the CDM Difference Video

At CDM Systems, the true difference in our equipment starts with the design and construction materials that go into every conveyor. The CDM Difference also includes our outstanding workmanship and exceptional approach to quality assurance and quality control. Because every conveying system we build is a big deal to our customers. Click here to learn more about The CDM Difference.