Conveying Systems Brochure

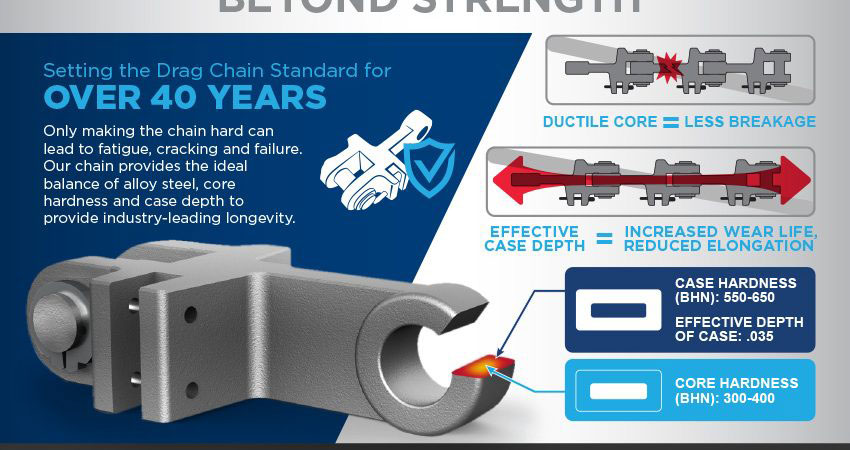

Serious Conveying Systems for Your Specific Application Our founders started CDM more than 40 years ago with the singular mission to provide our customers with the longest-lasting, most efficient conveyor systems for heavy-duty applications. Today our systems offer the best solutions to the bulk material-handling problems that face our global customer base. We deliver unmatched durability and value for even […]