CDM Systems Company Introduction Video

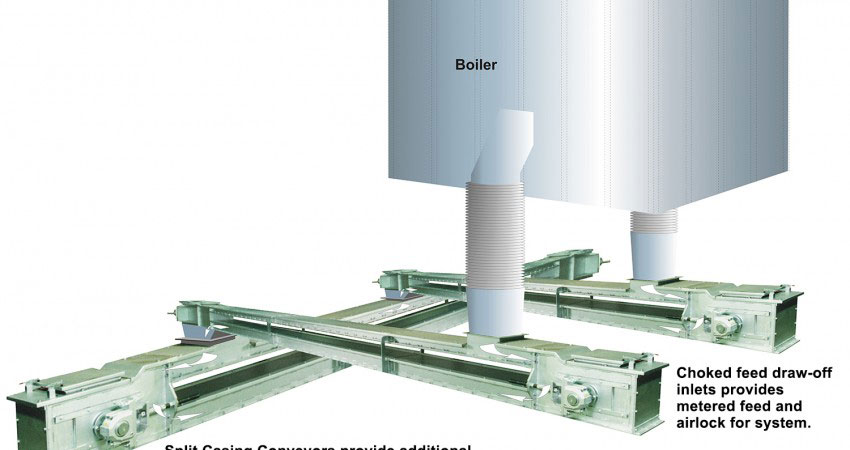

CDM Systems started more than 40 years ago under the premise that building the highest quality, longest-lasting conveyors for heavy-duty industrial applications started with the chain. Learn about our exclusive Drop-Forged Chain, Drag Chain Conveyors and company.