Case Study: Glass Cullet

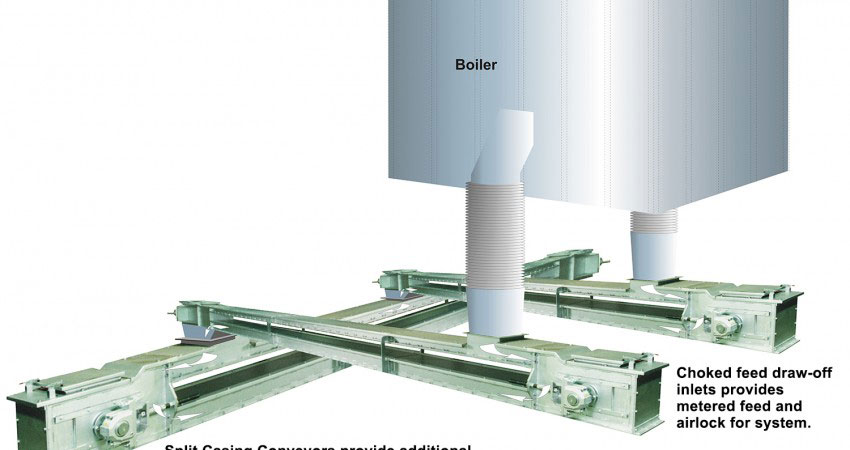

Fiberglass Manufacturer Reduces Maintenance Cost and Improves Operating Conditions with Drag Chain Conveyors CHALLENGE A global fiberglass insulation manufacturer sought an improved method for handling glass cullet and batch. The screw and belt conveyors used in all of the North American plants to move glass and bulk material were causing excessive maintenance and housekeeping issues and the unplanned […]