How an En-Masse Conveyor Can Pay You Back in the Pulp and Paper Industry

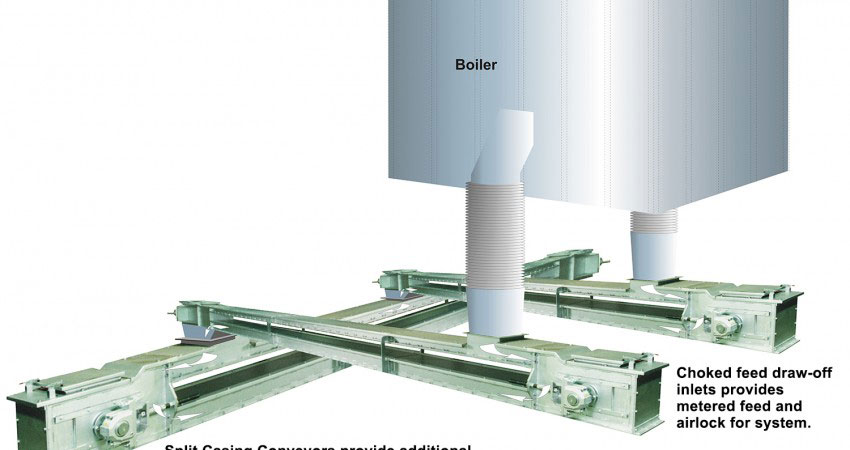

We understand the importance of having a conveyor you can not only trust to last in the harshest of conditions, but also to perform and allow you to hit your production goals by minimizing downtime. A pulp and paper mill in Pennsylvania was struggling with the subsequent costs of frequent downtime plaguing them due to the nature of their product […]